Maintaining the quality of Water for Injection (WFI) in storage and distribution systems is crucial for pharmaceutical and biotech applications. Once WFI is produced, it must be stored and distributed under conditions that prevent contamination and preserve its purity. This article provides an overview of best practices for maintaining WFI quality in storage and distribution systems.

Importance of WFI Storage and Distribution Quality

WFI is highly susceptible to contamination if not stored and distributed under controlled conditions. Any introduction of microorganisms, endotoxins, or particulates can compromise the quality of the WFI, making it unfit for use in injectable products. Therefore, quality assurance practices are essential to maintain the integrity of WFI system throughout storage and distribution.

Key Factors for Maintaining Quality

Sanitary Storage Tanks:

WFI storage tanks must be constructed from high-grade stainless steel to prevent corrosion and contamination. Tanks are typically equipped with sloped bottoms to facilitate complete drainage, ensuring that stagnant water does not accumulate, which could lead to microbial growth.Temperature Control and Recirculation:

WFI is often stored at elevated temperatures (typically around 80°C) to prevent microbial growth. Continuous recirculation of WFI helps maintain temperature and ensures that water quality remains consistent. Temperature control and recirculation are essential for reducing contamination risk in WFI systems.Clean-In-Place (CIP) Systems:

CIP systems are used to clean and sanitize WFI storage and distribution lines without disassembly. CIP operations typically involve hot water or chemical sanitization to eliminate any biofilm or microbial buildup within the system. This process ensures that the distribution system remains sterile and free from contaminants.Automated Monitoring and Alarms:

Automated monitoring systems track critical parameters such as temperature, flow rate, and microbial levels. Alarms notify operators of any deviations from set parameters, allowing for immediate corrective action. This continuous monitoring is essential for maintaining WFI quality in storage and distribution.

|

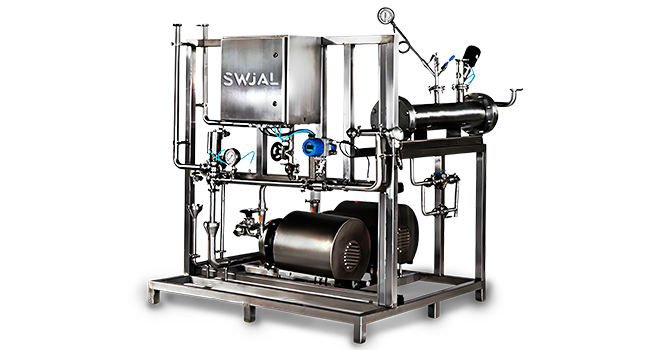

| Water Storage and Distribution System manufacturer in Mumbai, India |

Conclusion

Proper storage and distribution practices are essential to preserving the purity of Water for Injection. By utilizing sanitary storage tanks, temperature control, CIP systems,

No comments:

Post a Comment