Pure Steam Generator (PSG) systems are essential for industries requiring high-purity steam for sterilization, including pharmaceuticals, biotechnology, food processing, and healthcare. These systems ensure compliance with cGMP, USP, and FDA standards, delivering contamination-free steam for critical applications.

The demand for pure steam generation has significantly increased as industries recognize the importance of contamination-free environments. Pure steam generators ensure that sterilization processes remain effective by eliminating the risk of microbial contamination. The systems are specifically designed to provide steam with no entrained moisture, endotoxins, or non-condensable gases, making them ideal for sensitive industrial applications. As regulations around steam sterilization continue to evolve, PSG technology is becoming a standard requirement rather than an optional investment.

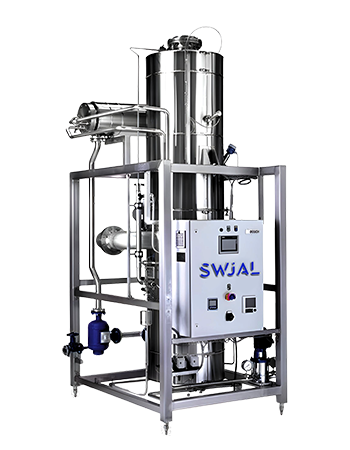

|

| Pure Steam Generator Plants |

Working Principle of a Pure Steam Generator

A Pure Steam Generator operates by converting pre-treated feedwater into pure steam through a controlled heating and separation process. The steps include:

Pre-treatment of Water – Demineralized or distilled water is used to prevent contaminants.

Heating Process – The water is heated using electrically powered or boiler-supplied energy sources.

Separation and Purification – The generated steam passes through separators and demisters, eliminating particulates, ensuring high-purity output.

Proper design and operation of a PSG system are crucial for maintaining consistent steam quality. Any deviation in water quality or temperature control can lead to inefficiencies in the steam production process. Advanced PSG systems incorporate automation and real-time monitoring to regulate steam purity, ensuring continuous compliance with international standards. The ability to produce pure steam on demand without fluctuations in quality makes these systems an essential investment for industries that require precise sterilization.

Applications of Pure Steam Generators

Pharmaceutical Industry: Sterilization of equipment, pipelines, and cleanroom environments.

Biotechnology: Used in fermentation processes and sterilization of bioreactors.

Healthcare: Surgical instrument sterilization and autoclaving.

Food Processing: Used in aseptic packaging and sterilization of food production lines.

Benefits of Using Pure Steam Generators

Microbial-free steam production prevents contamination.

Compliance with global standards (cGMP, USP, ASME BPE).

Reduced risk of endotoxins and particles, ensuring product safety.

Energy-efficient designs lower operational costs.

Pure steam generators offer a significant advantage over traditional boiler systems in terms of sterility assurance and operational efficiency. Since the steam produced is entirely free from non-condensable gases and particulate matter, it enhances product safety in pharmaceutical and biotech applications. Additionally, PSG systems reduce the risk of corrosion in steam distribution lines, ensuring longevity and reducing maintenance costs. As sustainability becomes a critical factor in industrial operations, many companies are investing in energy-efficient PSG systems to reduce their carbon footprint.

No comments:

Post a Comment